After the preparation of the parts is painted, the stacker of the panel is assembled and according to the documents and drawings relating to the boards of each project (supports) and (baseplates), the installation of components is completed and all the piercing, mastblade and installation of canals and rails and panels The installation is carried out with the delivery of equipment from the warehouse of the installation. After confirmation and control of the installation and the preparation of the shaft parts for drilling, bending, dyeing or scouring, paneling, and after the quality control, the operation of the wiring with Pay attention to the sizes and colors and the codes and decorations determined by design and engineer The thirty steps are carried out accurately.

Items and ducts that are installed in the assembly and testing unit of Fajr Shablo Industries

The nominal load current of the main line loads is 1.5 times the nominal current of the main switch, and the short circuit current withstand the key amps and bus bases.

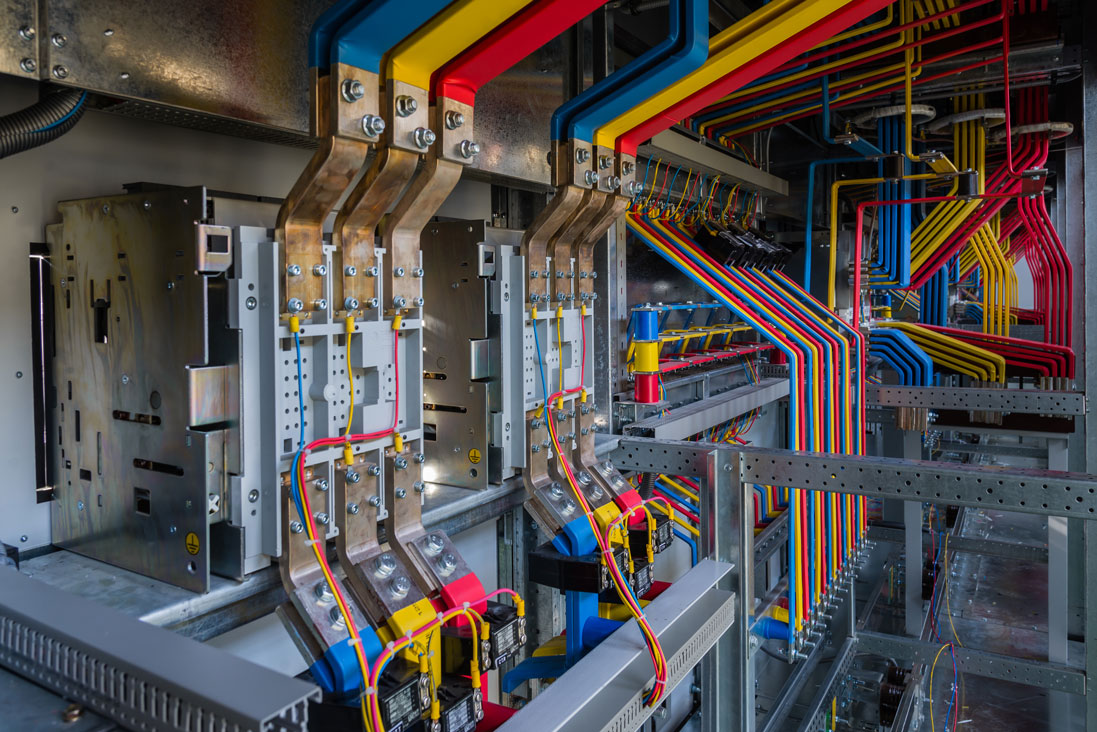

Bass loads or wires from hardened electrolytic materials with excellent conductivity of the copper company Bahonar

The bass section of the bars or null-wart shafts is at least half the length of the main or phase shaft

All basses of the main loads or wires for high conductivity and insulated or insulated safety shall be colored in accordance with standards (DVD) with a thickness of at least 100 microns. The use of standard heat sealing is allowed instead of color

All bases of the three-phase main loads and heat exchangers or paintings should be equipped with an engraved identification code in accordance with the power maps.

Suitably proportional to the number of output loads of fuzzy bushings and coiled tubes, and of all the individual connections.

The cutting and bending and scrubbing operations of the wires in the standard method should be avoided and the traditional methods should be avoided. Due to the absence of stress and tensile stresses and microscopic incisions of the busbars in the electrical conductivity of the machine with CNC machines,

Noll Wart bushes are separately installed in the output and input terminals and in multi-linking boards and galvanized bolts and galvanized M8x8 connectors and a single cloth.

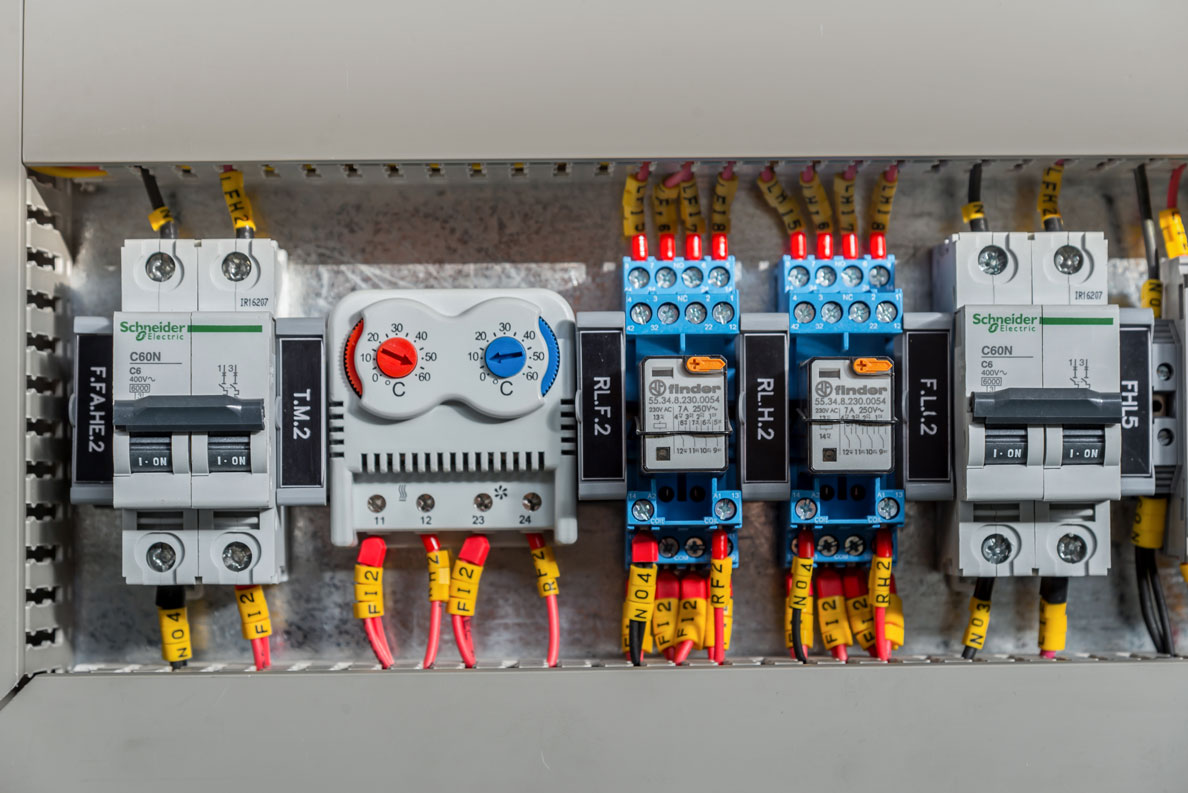

All of the main and secondary reliance of the mechanical and electrical bearing is short-circuited, and the existence of the typing test is compulsory.

All terminal and mini-rail lines of the selected standard should be avoided due to inconsistency with equipment assembly due to miscellaneous rails.

All door and hinged covers are wound by warp copper wires, screwed to the inside of the door and the bottom of the bus.

The cross-sectional strength of the wires according to the tables (VDI) and appropriate to the condition of the panel environment is selected and the minimum density for each millimeter square is 4 amps.

The minimum cross-sectional strength of the control wires in the low-pressure boards is 1.5 mm. The approval is valid and under no circumstances should be used with different wires.

All wiring or power cords are equipped with a map identification code and identification color of the phase, and validated and accredited companies can use the Tvnyr certification and carry out different wires.

All wire connections or power and control wires are connected by individual wires or standard cables.

All electrical power equipment - Measurement control - Input and output terminals equipped with an engraving identification code that conforms to electrical maps.

The installation of the equipment is made in a way that is accessible from the front and easy to repair and replace the parts.

All ventilation fans are equipped with a filter and air inlets in the lower area and air outlets in the upper part. Layout layout chart.

Conforming to the condition of the panel in the presence of a permanent heater, the work with the relevant thermostat and in the case of heat above 40-50 ° C, the gas cooler should be installed.

Power connection of all feeders above 100 amps by load bos

All electrical equipment should be purchased from reputable dealers and equipped with original holograms.

All equipment for medium pressure switchgear including Djangort-Squeezer-Transforms of current and voltage of protection wires equipped with original manufacturer's checklists.

In the middle pressure boards, all inlets and outlets are equipped with a capacitor insulator and a corresponding display. About operator protection

In medium pressure switchboards, if using Scythian and SF6 or SF6, a permanent heater is required to operate the thermostat.

In the middle pressure boards, all the standard intervals of observance of the criterion of potential test (s) are attended by the representative of the buyer.